- Water recycling

- Pure water equipment

- Filtration equipment

- Aeration equipment

- Quick settling tank

- Quick sedimentation tank

- Oil-water separator

- Screw type extruder

- Scraping machine for the settling tank

- Bio-membrane contact filter media

- Exclusive agents for wastewater treatment

- High efficiency pressurized floating removing equipment

- Fully automatic polymer preparation machine

- Home

- Product Info

- Exclusive agents for wastewater treatment

Wastewater treatment chemicalsAnti-scale agent, decoloring agent, agglutinant, coagulant

Anti-scale agent

The anti-scale agent is an inhibitor for scale and corrosion. Using the principle of neutralizing acids and bases, it can effectively remove water hardness and prevent scale, corrosion, and control impurities in water, avoiding scaling on the membrane tube and prolonging the membrane tube life. It is suitable for anti-scale agent and anti-corrosive agent of high silicate to reduce the acid amount of addition. It can also inhibit formation of deposits and create a protective film on the metal surface.

Benefits

- (1)Suitable for different kinds of water, with high performance of scale inhibiting ability.

- (2)Reducing scaling and reducing frequency of washing the membrane tube.

- (3)Able to reduce or replace the acid treatment of the membrane tube system.

- (4)Low dosing amount with better economical benefit.

- (5)Effective metal insulator.

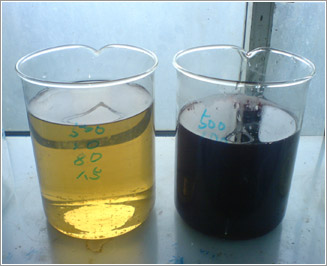

Decoloring agent

The wastewater decoloring agent is used in wastewater decoloring treatment in industries such as: textile, printing & dyeing, inking, leather, rubber, coking, paper-making and pharmaceutical, etc. In general, the decoloring agent is poly-aluminum chloride as well as metal salt with cations. In addition, there is high performance decoloring agent, which is organic polymers with strong positive electric charges. A small amount of it can achieve high performance of decoloring. It can remove colors to which the poly-aluminum chloride is unable and achieving final ideal water quality condition.

Coagulant is mainly divided into aluminum series and iron series. These two kinds of coagulants have slight decoloring capability but the result is not significant. The decoloring agent has better coagulation and decoloring effects than coagulant.

Benefits

- (1)It is currently the most economical and effective decoloring method using the chemical coagulation.

- (2)The decoloring effect of more than 90% can be achieved by adjusting the pH value and adding coagulant with different

pigments. - (3)If added with coagulant of PAC, aluminum salt, etc, the maximum decoloring rate is only 55%. With only a small dose of

decoloring agent, the decoloring rate can be as 95% of as with agglutinant. - (4)Together with the decoloring agent and coagulant, COD, BOD and SS can be removed or reduced at the same time, increasing the overall effect of wastewater treatment.

- (5)Able to reduce sludge amount and lower sludge handling costs.

Agglutinant

By its appearance, polymer agglutinant can be divided into transparent liquid type and powder polymer type. By its electric charge, it can be divided into four major series of polyacrylamide (PAM), which are non-ion, anion, cation, or both ions series. It can be used for separation of SS and liquids and is suitable for chemical coagulation of original water, chemical coagulation of wastewater, sludge dehydration and increasing bio-settlement transparency (or reducing the amount of SS). It can also expedite the settling speed of aluminum sulfate (Alum) or poly-aluminum chloride (PAC), driving a higher settling speed of SS, reducing water contents of agglutinated sludge, increasing the amount of treated water and treatment efficiency, and lowering sewage/wastewater operating costs and increasing efficiency.

Benefits

- (1)It does not quickly consume the alkalinity in water, having no significant effect to the pH value.

- (2)It can expedite agglutination to form bigger flocs to increase the settling speed, increasing the handling efficiency of the

settling tank. - (3)Able to reduce the amount of inorganic type agglutinant, lowering the handling costs.

- (4)Producing lesser amount of sludge and has good dehydration.

Coagulant

Coagulants are mainly aluminum salts such as aluminum sulfate and poly-aluminum chloride, etc. When coagulant is added in water, due to hydrolysis, aluminum hydroxide with positive charges and its polymers are generated. In addition, the surfaces of micro-particles of colloidal suspension in water are carrying negative charges. According to the principle that like charges repel each other, unlike charges attract, after micro-particles with negative charges attract aluminum hydroxide polymer carrying with positive charges with each other, colloidal micro-particles will become larger particles due to collision. In the meantime, inorganic and organic substances, bacteria and microorganisms will continue to accumulate and grow due to attraction and become easy settling flocs.

Poly-aluminum chloride [(Al2 (OH) nCl6-n) m] (i.e. PAC) is liquid coagulant that is polymerized aluminum chloride with water. PAC can be used alone, having better effect than aluminum sulfate with addition of coagulant aid.

- (1)Has better coagulating effect than aluminum sulfide. The higher turbidity of original water, the more significant effect

than aluminum sulfate has. - (2)The coagulating effects for original water with low or high turbidity or mud with color are all very good.

- (3)Suitable for a wide range of pH values.

- (4)Consumes low alkalinity in water, floc forming is quicker, larger flocs with quicker settling speed.

- (5)The coagulating effect is not affected even in cold water. Also, the filtration layer is not penetrated during filtering.