- Water recycling

- Pure water equipment

- Filtration equipment

- Aeration equipment

- Quick settling tank

- Quick sedimentation tank

- Oil-water separator

- Screw type extruder

- Scraping machine for the settling tank

- Bio-membrane contact filter media

- Exclusive agents for wastewater treatment

- High efficiency pressurized floating removing equipment

- Fully automatic polymer preparation machine

- Home

- Product Info

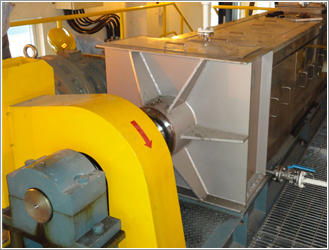

- Screw type extruder

Screw type extruder

Product principle

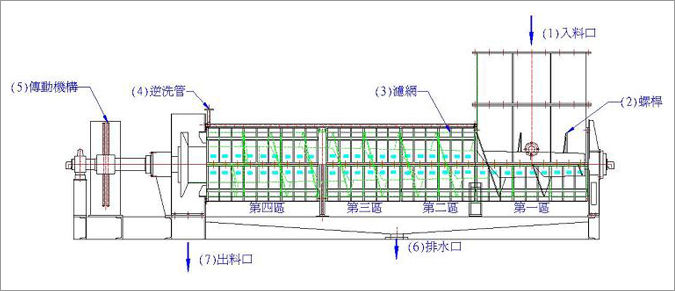

By using the principle of screw delivery and squeezing, water flows out from the metal screen mesh while the pressure is increasing and the mesh hole of the filter is decreasing, achieving the purpose of wastewater dehydration.

Product structure

(1)Inlet:sludge flows in the filter by gravity from the outlet of the mixing tank. A liquid level switch can be installed

additionally on the top for automatic handling of sludge.

(2)Screwrod :the screwrod is the heart of the screw type extruder, which has sludge delivery and extrusion functions.

The threads are screw type with variable lead screw design, which can slowly squeeze sludge out of water.

(3)Filter:its main purpose is to filter out water. The flow distribution is mainly divided into three sections in accordance

with the sludge property

1.Sludge compression section: It squares out of excessive water from sludge.

2.Water pre-compression section: It pre-compresses sludge into a sludge cake.

3.Sludge cake compression section: It compresses the sludge cake with high compressive pressure to low water

contents in sludge.

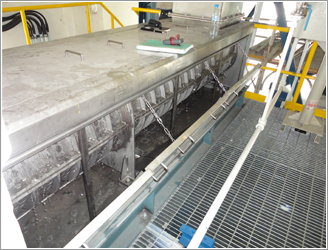

(4)Washing device:When handling sludge, the mesh holes on the surface layer of the filter is easy to clog, which affects

water contents in the sludge cake. A cleaning pipe is designed to periodically wash the mesh holes to

avoid clogging with sludge.

(5)Transmission mechanism:Operation is made through the transmission equipment of the sprocket and chains, which are

driven by a high-torque reducer motor.

(6)Water discharge hole:Sludge filtered water and cleaning water are collected in the water pan of the machine, which will

be then discharged to the wastewater collecting tank or settling tank for treatment.

(7)Outlet:at the sludge outlet, the backpressure can be adjusted and the sludge cake can be scraped off, which is then

delivered to sludge storage tank or the conveyor to facilitate sludge transportation.

螺桿式與其他款式比較

| 項目 Contents |

螺桿式擠壓機 Screw press |

皮帶式脫水機 Belt press |

板框式脫水機 Filter press |

|---|---|---|---|

| 全自動化運轉 Full automation and continuous operation |

◎ | X | |

| 操作環境 Environment |

◎ | X | X |

| 設備保養 Maintenance |

◎ | X | |

| 清洗用水 Screen wash |

◎ | X | X |

| 泥餅含水率 Moisture content |

◎ | X | X |

| 節能 Economize on electricity |

◎ | X | |

| 運轉成本 Running cost |

◎ | X |

符號(Symbol):◎表示〝優〞(Excellent) ![]() 表示〝尚可〞(Good) X 表示〝不佳〞(Bad)

表示〝尚可〞(Good) X 表示〝不佳〞(Bad)

|

生物 污泥 Bio sludge |

化學 污泥 Chem- ical |

化纖 污泥 Chem- ical& fiber |

FGD 污泥 FGD sludge |

原水 污泥 Raw water |

紙漿 泥水 Pulp& paper |

重油 污泥 Oil sludge |

PCB 污泥 PCB sludge |

研磨 污泥 Putty sludge |

|

|---|---|---|---|---|---|---|---|---|---|---|

| 污泥擠壓機 Screw press |

85% | 80% | 80% | 40% | 55% | 52% | 75% | 75% | 70% | |

| 皮帶式脫水機 Belt press |

90% | 87% | 90% | 60% | 70% | 70% | 90% | 87% | 80% | |

| 板框式脫水機 Filter press |

87% | 85% | 85% | 40% | 60% | 60% | 85% | 85% | 75% | |

Product features

1.Small size with a small footprint.

2.Least problems on mechanical failures.

3.Fully enclosed design, avoiding escape of unpleasant odor.

4.No consumables, saving operating costs.