- Water recycling

- Pure water equipment

- Filtration equipment

- Aeration equipment

- Quick settling tank

- Quick sedimentation tank

- Oil-water separator

- Screw type extruder

- Scraping machine for the settling tank

- Bio-membrane contact filter media

- Exclusive agents for wastewater treatment

- High efficiency pressurized floating removing equipment

- Fully automatic polymer preparation machine

- Home

- Product Info

- High efficiency aerator disc

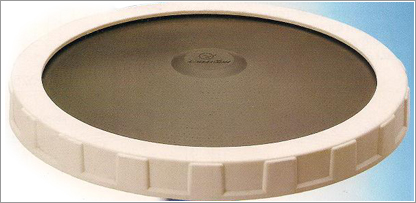

High efficiency aerator disc

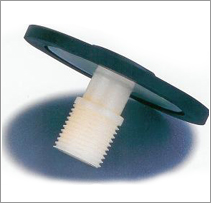

High efficiency aerator disc (coarse bubbles)

The coarse bubble type produces larger bubbles with a diameter of 5~8 mm. The oxygen transfer efficiency is 4~8%. It is mainly used in wastewater agitating. Its advantage is that it has a low possibility of clogging, low air purification requirement, low initial installation cost, low maintenance lost. It has a sturdy and durable structure with the function of anti-reverse flow. It never clogs and has high anti-corrosive ability.

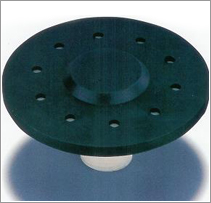

High efficient diffuser disc (fine bubbles)

The fine bubble diffuser disc produces fine bubbles with a diameter of 1~3 mm. The liquid motion in the aerating tank is slower. The oxygen transfer efficiency is 8~12%. The membrane is made from EPDM rubber and the support body is made from ABS. It can be used in the intermittent operation system and also in the continuous operation system. The special perforating technique enables apertures of the diffuser disc to close when operation is stopped, effectively preventing wastewater from counterflow and microorganism attachment and growth.

It is mainly used in the aeration tank (biological tank) for wastewater treatment. The oxygen transfer speed is high, which can reduce the designed flow of the blower. The reaction time is short, and the check rink design can effectively prevent wastewater from counterflow, avoiding damage to the aerating equipment and the pipeline.

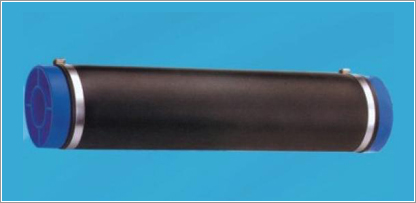

Diffuser tube

The structure of this product is made from ABS and PVC, which are resistant to acids and bases and corrosion. With the hollow design, it can eliminate floating force. The aerating membrane is finely made from EPDM rubber, which effectively inhibits the aerating membrane from ageing, extending its surface life.

Benefits of the diffuser tube: High efficient oxygen transfer, wide air flow, low energy cost, and effectively avoiding clogging also with automatic cleaning effect and strong intermittent operation ability.